Supply chain is a crucial part for the functioning of any company. But is it going to be the source of a company’s success or failure? That depends on many internal and external factors. Supply chain poses numerous business risks (strategic, compliance, operational, financial, reputational, legal) and there have been way too many cases where suppliers found to be using modern slavery, damaging the environment, misusing sensitive data, breaking laws, etc.

While risk of revealing flaws has always existed, thanks to rising awareness and/or shaming campaigns, social media and ’watch dog’ groups, these non-addressed problems can very quickly damage a company’s reputation nowadays. According to a study by the World Economic Forum, on average more than 25% of a company’s market value is directly attributable to its reputation. Having these potential risks in mind, wise and forward looking companies are investing in assessments of their supply chain practices, knowing that collection of relevant supplier data can be used to reduce exposure to reputational risks and consequent economic losses.

However, the problem is that most companies have the tendency to act on a more reactive basis when it comes to supply chain assessments and therefore, instead of preventing risks and threats (supported by relevant data) or mitigating them, they are mainly reacting when they have already occurred. This however is not reputational risk management – it is crisis management, and it brings much higher financial and reputational costs to both the company and its suppliers.

Good and Bad News Travel Fast… and Wide

Sustainability performance does not only apply to companies that produce the products, provide the services or sell consumer produces, but equally to their supply chain.

How? Well, more directly, it will be negatively influencing their reputation (and consequently causing economic loss) and disturbing their operations (and consequently creating and building up economic loss).

According to the McKinsey & Company research from 2016, a typical consumer company’s supply chain creates far greater social and environmental costs (reputational risks) than its own operations, accounting for:

- more than 80% of greenhouse-gas emissions.

- more than 90% of the impact on air, land, water, biodiversity, and geological resources.

- more than 80% of violation of labour rights, human rights, health conditions and other types of negative social impacts.

Hult Research & Ethical Trading Initiative survey of global firms highlighted that 77% of companies thought there is a likelihood of modern slavery occurring in their supply chains. Around 40 million people are experiencing some kind of modern slavery today out of which, 62% are trapped in forced labor (11 million in construction, manufacturing and agriculture and the rest in textile, plantations, food processing, extraction of coal, gold, diamonds, etc.).

Besides modern slavery, there are many examples of irresponsible labor and health and safety practices, for example some factories in Asia caused both reputational and economic losses. The following are just few of such cases:

- Nike has been accused of using sweatshops since the early 1970s when it produced goods in South Korea, Mainland China and Taiwan. Excuses were made that Nike did not own the factories and that Nike has never manufactured a single shoe in its entire history. However, when the photo of a child stitching footballs that carried the Nike logo appeared in newspapers, there was no doubt that Nike and child labor practices in its supply chain are ‘the same’. Everything changed for better in 1996 when Nike owned up responsibility and came up with new codes and conducts, transparently released the names and locations of its factories, and cancelled its contract with many of its unethical suppliers. There was a significant cost to dealing with this problem and it took more than one decade for Nike to regain some kind of respect and to start to change its reputation. It was a painful process and it required a lot of changes and investments but recently published articles now present Nike as one of the success stories of corporate integrity in the last two decades.

- Working conditions within the supply chain at H&M, Gap, Walmart and some other apparel brands have caused death of 1,138 workers who were killed when the Rana Plaza factory collapsed in Bangladesh in 2013. The world’s worst garment factory disaster brought to light health and safety issues (no fire exits, overheated work space), working conditions (threats of contract termination, forced overtime up to 17 hours a day, denial of sick leave, taken personal documents), child labor and fair pay (dismissed workers were often let go without receiving their due wages and benefits) and other issues that many of those who were responsible had been turning blind eye to. Various shaming and advocacy campaigns are still on-going, many audits and studies have been conducted by Wage Alliance and ILO, Accords and Codes of Conducts have been signed, yet progress has been very slow. Change is now happening, and so far, the greatest achievement is that companies know that someone is watching what they are (not) doing.

- Working conditions within the supply chain at H&M, Gap, Walmart and some other apparel brands have caused death of 1,138 workers who were killed when the Rana Plaza factory collapsed in Bangladesh in 2013. The world’s worst garment factory disaster brought to light health and safety issues (no fire exits, overheated work space), working conditions (threats of contract termination, forced overtime up to 17 hours a day, denial of sick leave, taken personal documents), child labor and fair pay (dismissed workers were often let go without receiving their due wages and benefits) and other issues that many of those who were responsible had been turning blind eye to. Various shaming and advocacy campaigns are still on-going, many audits and studies have been conducted by Wage Alliance and ILO, Accords and Codes of Conducts have been signed, yet progress has been very slow. Change is now happening, and so far, the greatest achievement is that companies know that someone is watching what they are (not) doing.

- In 2016 Nestlé was suspended by the Roundtable on Sustainable Palm Oil (RSPO) and was no longer able to claim usage of certified sustainable palm oil for its chocolates and other products. There are many speculations on motives behind the RSPO suspension and even more criticism that RSPO has been too soft on member companies who are engaged in deforestation and human rights abuses that workers at palm oil plantations are experiencing. Whatever the motives are, the fact is that one of the big institutional investors such as Norges Bank’s Government Pension Fund Global (the world’s largest sovereign wealth fund) divested in 2018/2019 from palm oil companies in Malaysia and Indonesia due to non-compliance with ESG criteria i.e. environmental (climate change, water management) and social sustainability factors (violations of human and labour rights, health and safety, links to tobacco production).

Luckily, transparency in supply chain is evolving and with rapid expansion of data, it becomes much easier to make connections between companies, their supply chain and buyers. Connecting these three dots will bring us closer to better assessment of real positive and negative impacts that companies and their supply chain are achieving.

Sustainability performance and economic gains or losses of one company also depends on having alternative Tier 1 and Tier 2 suppliers who comply with sustainability requirements. The Thai floods in 2011 resulted in 800 factories (core operations and supply chain) affected, economic loss of US$45 billion (13% of Thai GDP) and increased global textile prices by 28% following the flooding. Many companies who did not have alternative suppliers faced tremendous financial loss. Meanwhile, floods in Kelantan, Pahang and Terenganu in 2014 resulted in US$280 million of economic losses and 184.000 hectars of palm plantations affected.

The same goes with draughts and other effects of climate change. These are all reasons why responsible companies are assessing their supply chain practices and adopting more effective methods for nurturing their suppliers’ practices towards environmental and social sustainability requirements.

ESG Supply Chain Reporting

Global Reporting Initiative (GRI) is the world’s most widely used sustainability reporting framework that defines what aspects of supply chain should be assessed to identify and address their (un)sustainable practices. Bursa Malaysia Sustainability Reporting Guide for PLCs is also based on the GRI criteria.

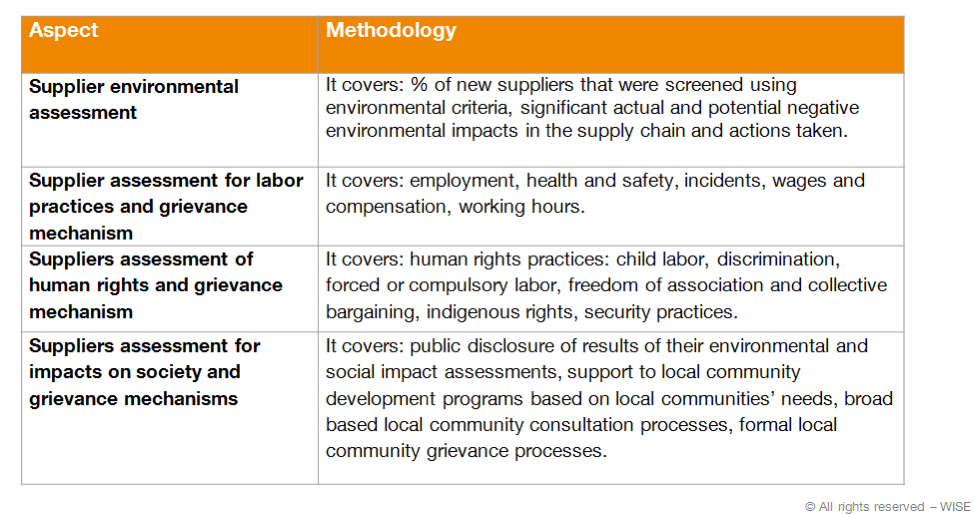

The following are four aspects of suppliers performance that reporting about environmental and social component of sustainability should cover.

- These are the same aspects and criteria that regulators, standard setters, assurers, ESG data providers and investors will be looking at regardless of the industry or sector.Having this in mind, it seems that even if you don’t think that unsustainable performance of your supply chain is not the responsibility of your company, there are many decision/investment makers who will think that it is.

This article is written by Dr Jasmina Kuka, CEO of W!SE (Working on Impact and Social Empowerment) and expert in impact assessment and sustainability practices.

Photo by Reproductive Health Supplies Coalition on Unsplash.

4.8

4.8